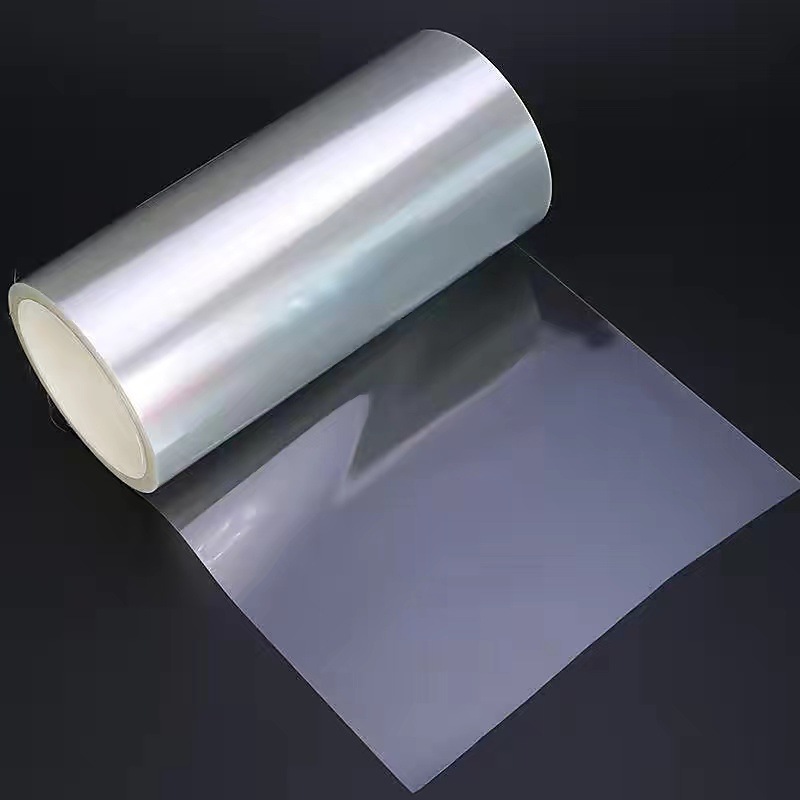

Release film, also known as peeling film or release liner, is a type of plastic film with a separable surface, which is treated with plasma, or coated with fluorine, or coated with silicone release agent on the film material, such as PET, PE, OPP, etc., It shows extremely light and stable release force for various organic pressure-sensitive adhesives, mainly composed of substrate, primer and release agent.

Release Film’s Classification:

1. Release film can be classified according to different substrates: PE Release Film, PET Release Film, OPP Release Film, or Recombination Release Film(it refers to the substrate composed by two or more types of material)

2. Release film can also be classified according to different release forces: Light Release Film, Medium Release Film, and Heavy Release Film.

3. Besides of that, Release film can be classified according to different colors: Red PET Release Film, Yellow PET Release Film, Green PET Release Film, Blue PET Release Film, etc.

4. Release film can be classified according to different treatments on surface: Single Side Silicone Oil Coated Release Film, Double Side Silicone Oil Coated Release Film, Silicone-free Release Film, Fluorine Release Film, Single Corona or Double Corona Release Film, Frosted Release Film, Matte Release Film, etc.

5. Release film can be classified according to different materials: Polyester Silicone Oil Coated Release Film, PE Release Film, OPP Release Film, etc.

Thickness range of Polyester release film: 12um, 19um, 25um, 38um, 50um, 75um, 100um, 125um, 188um.

The application of Polyester Release Film:

1. Applied to Adhesive Die Cut and Lamination

As a kind of most common release material, polyester release film is widely used as a base film during the adhesive tape manufacturing, like coating process, precision die cutting process and lamination process. The release film can decrease the absorption force from the adhesive side and achieve release effect from adhesive tapes and also prevent the tapes from dust, scratching during the tape processing.

2. Applied to Electronic Industry and Metal Material Industry

PET release film can also be used in the production of PET protective film materials, so it can not only be used for the protection of panels such as stainless steel, nameplates and aluminum plates, as well as the protection of notebook computer casings and display screens, but also for electronic die-cutting to provide protection during the manufacturing of electronic components.

3. Applied to Packaging Industry

PET release film can be formed as a kind of aluminized cardboard with metallic luster after being aluminized by vacuum aluminizer. It is characterized by degradable and recyclable environmental protection properties. It is a newly developed type of packaging material which is green, environmental ,and high end quality.

4. Applied to Printing Industry

PET release film can also be used as a type of transfer film. It can be used repeatedly on the printing industry. Treated by special process, PET release film can transfer the printed graphic on the glass, porcelain, plastic, metal, leather, and cotton fabrics by heating and pressing, moreover, it can also be used in high-tech industries with high integration of chemical industry, plate making, evaporation, precision molding industry.

5. Applied to Other Industries

The first-class PET release film can be made into PET reflective film through a special process. It features excellent optical properties, thermal stability and light aging resistance. And it is mainly used in traffic reflective signs, billboar

Post time: Nov-05-2024